To Build Electric Cars, Jaguar Land Rover Had to Redesign the Factory

To Build Electric Cars, Jaguar Land Rover Had to Redesign the Factory

Jaguar Land Rover, the iconic British car manufacturer, recently made the bold decision to shift towards electric…

To Build Electric Cars, Jaguar Land Rover Had to Redesign the Factory

Jaguar Land Rover, the iconic British car manufacturer, recently made the bold decision to shift towards electric vehicles. This meant rethinking their entire manufacturing process and reconfiguring their factories to accommodate the new technology.

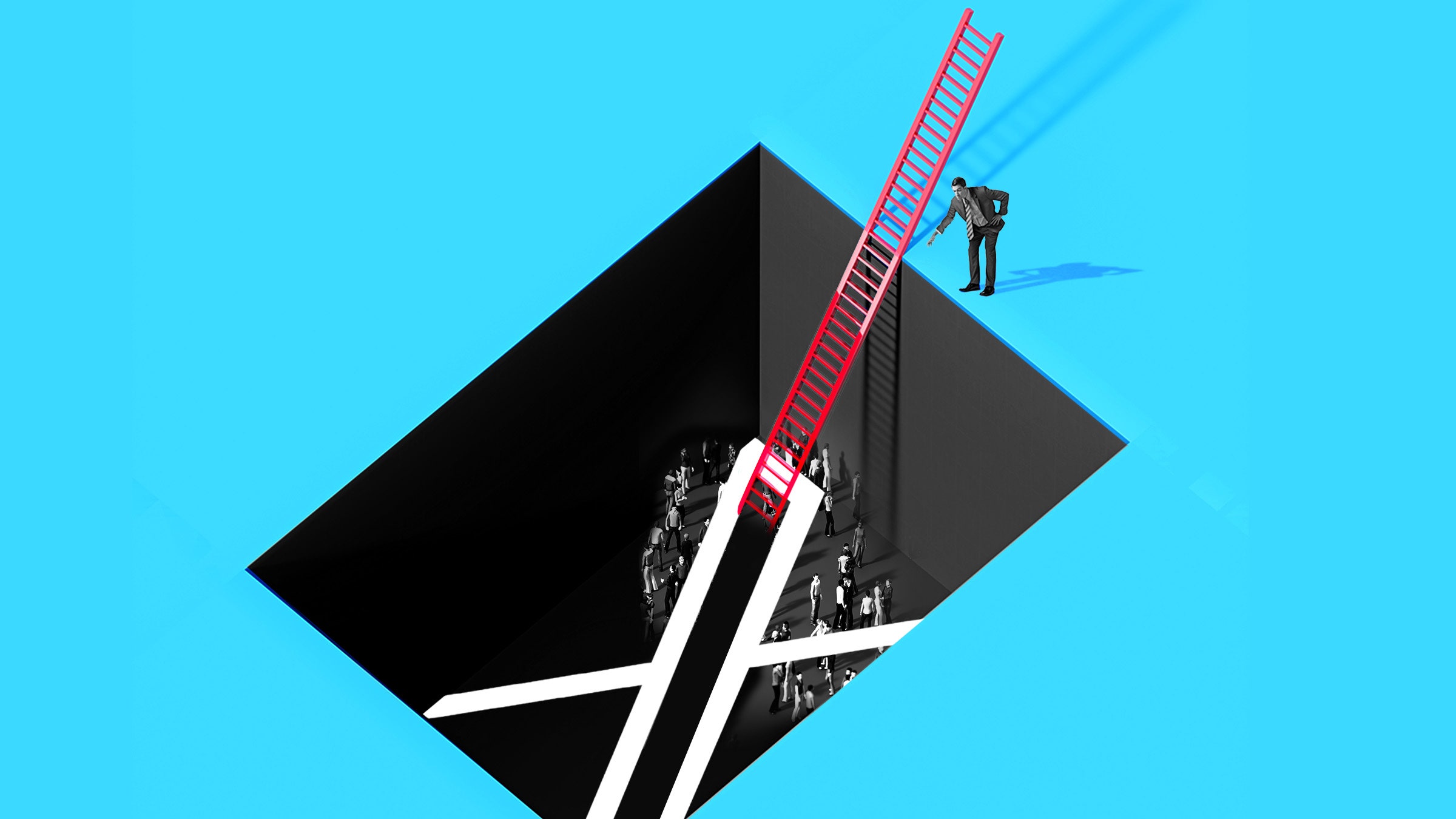

One of the key challenges they faced was redesigning the factory floor to accommodate the new electric vehicle assembly line. This required extensive planning and coordination to ensure that everything from the layout of the production line to the placement of electrical outlets was optimized for electric vehicle production.

Another major hurdle was retraining their workforce to adapt to the new technology. Jaguar Land Rover invested heavily in training programs to ensure that their employees were equipped with the necessary skills to build electric cars.

Additionally, the company had to work closely with suppliers to source the necessary components for their electric vehicles. This involved finding new suppliers for specialized parts like batteries and electric motors, as well as ensuring that existing suppliers were able to meet the increased demand for electric vehicle components.

Despite the challenges, Jaguar Land Rover’s efforts have paid off. The company successfully launched its first electric vehicle, the Jaguar I-PACE, to critical acclaim and strong sales.

By redesigning their factory and retraining their workforce, Jaguar Land Rover has positioned itself as a leader in the electric vehicle market and is well-equipped to meet the growing demand for sustainable transportation.